( Gabatarwa)

A cikin duniyar bututu da tubing, akwai nau'ikan hanyoyin samar da kayayyaki iri-iri, kowannensu yana da nasa halaye da aikace-aikacensa. Daga cikin wadannan, Electric Resistance Welding (ERW) ya yi fice a matsayin wata babbar dabarar samar da bututun karfe. Amma menene ainihin bututun ERW? Fahimtar ma'anar bututun ERW yana da mahimmanci ga duk wanda ke da hannu a masana'antu waɗanda suka dogara da ingantaccen tsarin bututun. Wannan shafin yanar gizon zai shiga cikin cikakkun bayanai na bututun ERW, yana bayanin tsarin masana'anta, fa'idodi, aikace-aikace, da dalilin da yasa'sa m bangaren a daban-daban sassa.

(Ma'anar ERW Pipe)

Bari mu fara da ma'anar bututun ERW. ERW yana nufin Welding Resistance Electric. ERW bututu nau'i ne na bututun ƙarfe da aka kera ta hanyar walda ɗinkin tsiri na ƙarfe ko naɗa a tsayi ta hanyar amfani da juriya na lantarki. Ba kamar bututu maras sumul ba, waɗanda aka samo su daga ƙarfe guda ɗaya, ana ƙirƙirar bututun ERW ta hanyar mirgina farantin karfe mai lebur zuwa sifa mai silinda sannan a haɗa gefuna tare.

(Tsarin Masana'antu: Duban Kusa)

Tsarin kera bututun ERW ya ƙunshi matakai da yawa:

Shirye-shiryen Karfe: An zaɓi ƙwanƙolin ƙarfe mai inganci ko coils dangane da ƙayyadaddun bututun da ake so.

Ƙirƙira: Ƙarfe yana samuwa a hankali ya zama siffa ta siliki ta amfani da jerin rollers.

Welding: Anan ne sihirin "Resistance Welding" ke faruwa. An haɗa gefuna na silinda da aka kafa tare, kuma ana ratsa su ta hanyar wutar lantarki mai girma amperage. Juriya ga wannan halin yanzu yana haifar da zafi mai tsanani, wanda ke narkar da gefuna kuma ya haɗa su tare, samar da ƙarfi, waldi mai tsayi.

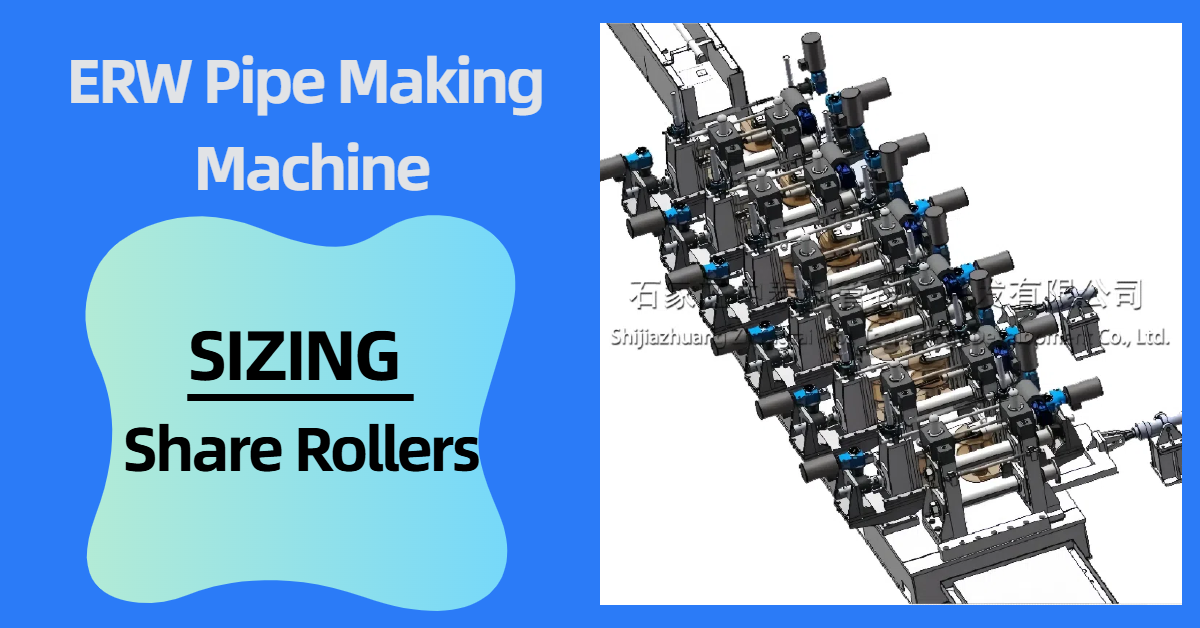

Girma da Siffatawa: Bayan waldawa, bututun ya ratsa ta cikin rollers masu girman girman don cimma diamita da siffar da ake so.

Yankewa da Kammalawa: Ana yanke bututun zuwa tsayin da ake buƙata kuma ana aiwatar da ayyukan gamawa kamar ɓata lokaci, daidaitawa, da gwaji.

(Amfanin ERW Pipe)

ERW bututu yana ba da fa'idodi da yawa waɗanda suka sa ya zama sanannen zaɓi a aikace-aikace da yawa:

Tasirin Kuɗi: ERW bututu gabaɗaya ya fi tsada-tasiri don samarwa idan aka kwatanta da bututu maras kyau, yana mai da shi zaɓi mai dacewa da kasafin kuɗi.

Daidaitaccen Kaurin bango: Tsarin ERW yana ba da damar sarrafa daidaitaccen kaurin bangon bututu.

Kyakkyawar Ƙarfin Weld: Dabarun ERW na zamani suna samar da walda waɗanda suke da ƙarfi kamar, ko ma sun fi ƙarfin ƙarfe na tushe.

Faɗin Girman Girma: Ana iya kera bututun ERW a cikin kewayon diamita da kauri.

Juyawa: Ya dace da aikace-aikace iri-iri, daga tallafi na tsari zuwa jigilar ruwa.

(Aikace-aikace na ERW Pipe)

ERW bututu yana samun amfani mai yawa a cikin masana'antu da aikace-aikace iri-iri:

Man Fetur da Gas: Don bututu, casings, da tubing.

Gina: A matsayin abubuwan da aka tsara a cikin gine-gine da ayyukan gine-gine.

Jirgin Ruwa: Don jigilar ruwa a cikin ƙananan hukumomi da na masana'antu.

Mota: Don tsarin shaye-shaye da sauran abubuwan da aka gyara.

Manufacturing: A cikin matakai daban-daban na masana'antu da ke buƙatar jigilar ruwa ko iskar gas.

Zane-zane: Ana amfani da shi don tsayayyen tsari mai aminci.

(ERW Pipe vs. Bututu maras kyau)

Duk da yake duka ERW da bututun da ba su da kyau suna yin amfani da dalilai iri ɗaya, sun bambanta sosai a cikin tsarin ƙirar su da halayensu. Bututu marasa ƙarfi suna ba da ƙarfi mafi girma kuma galibi ana fifita su don aikace-aikacen matsa lamba. Duk da haka, bututun ERW gabaɗaya sun fi tsada-tasiri kuma sun dace da aikace-aikacen da yawa inda ba a buƙatar matsananciyar juriya. Fahimtar bambance-bambance tsakanin bututun ERW vs bututu mara nauyi yana da mahimmanci yayin zabar kayan da ya dace don takamaiman bukatunku.

(Gudunmawar Kayan Aikin Kaya)

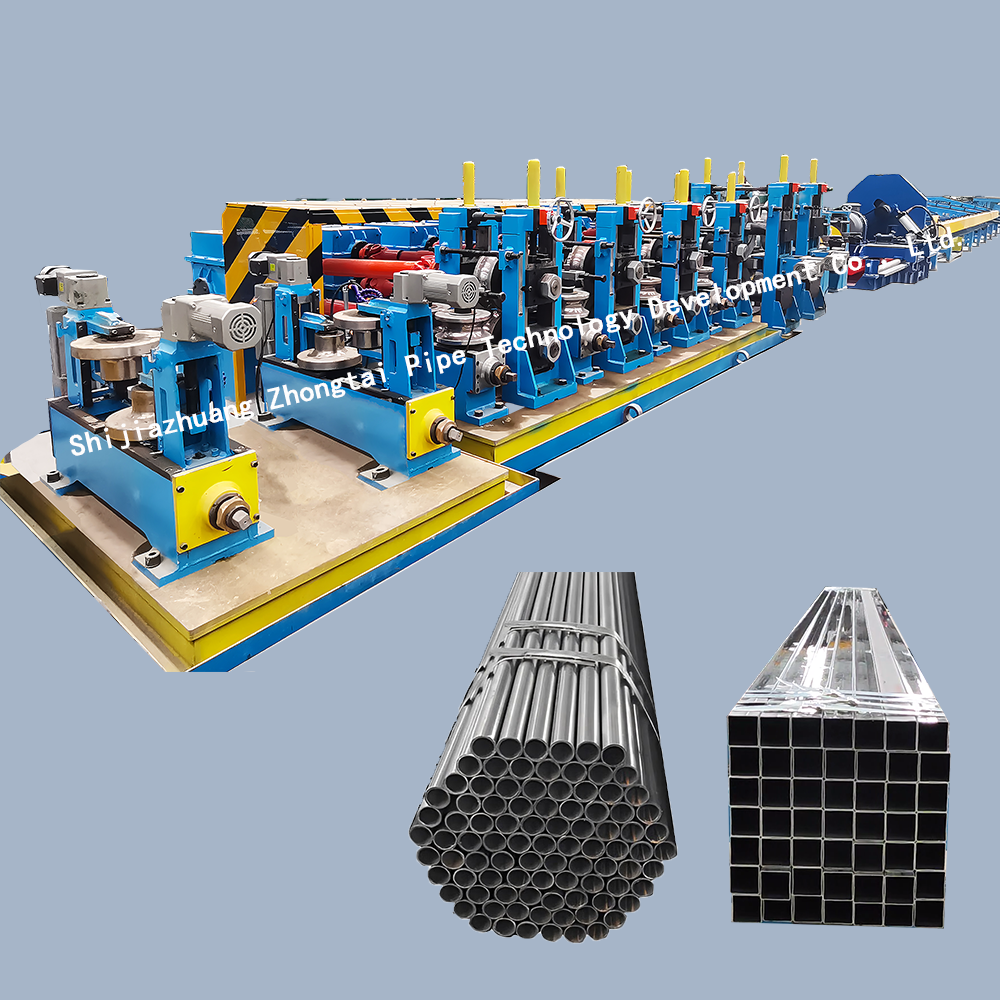

Samar da bututun ERW mai inganci ya dogara kacokan akan kayan aikin masana'antu na ci gaba. Wannan ya haɗa da:

Uncoilers da Accumulators: Don ciyar da coils na karfe da kyau a cikin layin samarwa.

Ƙirƙirar Mills: Don a hankali a siffanta tsiri na ƙarfe zuwa siffa mai siliki.

Injin walda: Zuciyar tsarin ERW, samar da daidaitaccen walda mai dogaro.

Girman Mills: Don tabbatar da ingantattun girman bututu.

Injin Yankan: Don yanke bututu zuwa tsayin da ake so.

Gwaji da Kayan Aiki: Don tabbatar da bututun ya cika ka'idodin ingancin da ake buƙata.

Idan kuna neman kera bututun ERW, zabar kayan aikin da suka dace yana da mahimmanci.

(Kammalawa)

Fahimtar ma'anar bututun ERW da tsarin da ke bayan ƙirƙirarsa yana da mahimmanci ga duk wanda ke aiki da bututun ƙarfe. ERW bututu yana ba da ingantaccen farashi kuma mai dacewa da mafita don aikace-aikacen da yawa. Ta fahimtar fa'idodinsa da gazawarsa, za ku iya yanke shawara game da lokacin da kuma inda za ku yi amfani da wannan muhimmin abu. Bugu da ƙari kuma, zaɓin kayan aikin masana'anta daidai yake da mahimmanci don samar da bututun ERW waɗanda suka dace da ka'idodin masana'antu da tsammanin abokin ciniki.

(Kira zuwa Aiki)

Shin kuna neman abin dogaro da ingantaccen kayan aikin masana'antar bututun ERW? Tuntube mu a yau don ƙarin koyo game da hanyoyinmu da kuma yadda za mu iya taimaka muku haɓaka tsarin samar da ku!

Lokacin aikawa: Fabrairu-19-2025